At present, industrial motor, fan, air compressor, stamping machine, water pump, numerical control machine tool, engineering machinery and other equipment are widely used in coal, electric power, chemical and mechanical manufacturing industries. Due to manual spot inspection, the staff can not monitor the equipment operation data for a long time in the harsh environment of noise, dust and strong interference, and the equipment is damaged due to bearing wear and imbalance Unable to be found in time, resulting in frequent mechanical failures, resulting in unexpected production stoppage, thus bringing huge losses to enterprises.

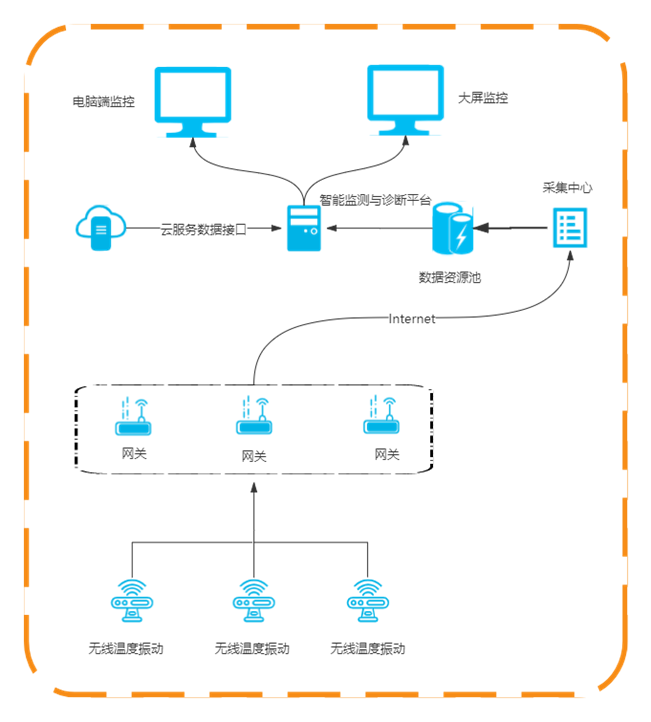

Jinan Jiahong Technology Co., Ltd. uses the Internet of things, cloud computing, big data and artificial intelligence and other cutting-edge technologies, relying on multi-dimensional information collection and accurate sensor detection technology, develops an intelligent monitoring and diagnosis system for equipment. The system is composed of software platform, gateway and sensor, which integrates feature collection, monitoring, intelligent early warning, intelligent diagnosis, model training and data visualization.

System features:

1. The installation is flexible and convenient: the sensor does not need network and power engineering wiring

Magnetic suction or screw thread fixed installation, flexible and convenient.

2. Equipment online management: gateway and sensor adopt online unified management

At present, the gateway starts and stops, loses the connection fault alarm.

3. Multi dimensional in one acquisition: wireless sensor equipment set temperature and three-axis vibration, etc

Dimensional data collection in one.

4. Intelligent monitoring and early warning: real time monitoring of equipment operation status, intelligent comparison abnormal

Data, fault warning.

5. Neural network algorithm: rely on neural network algorithm to extract equipment operation characteristics

Fault model training database is constructed.

6. Cloud intelligent diagnosis: the intelligent algorithm and cloud processing are effectively combined to achieve

And assist to compare with the equipment fault diagnosis model

The nursing staff "foresee maintenance".

System functions:

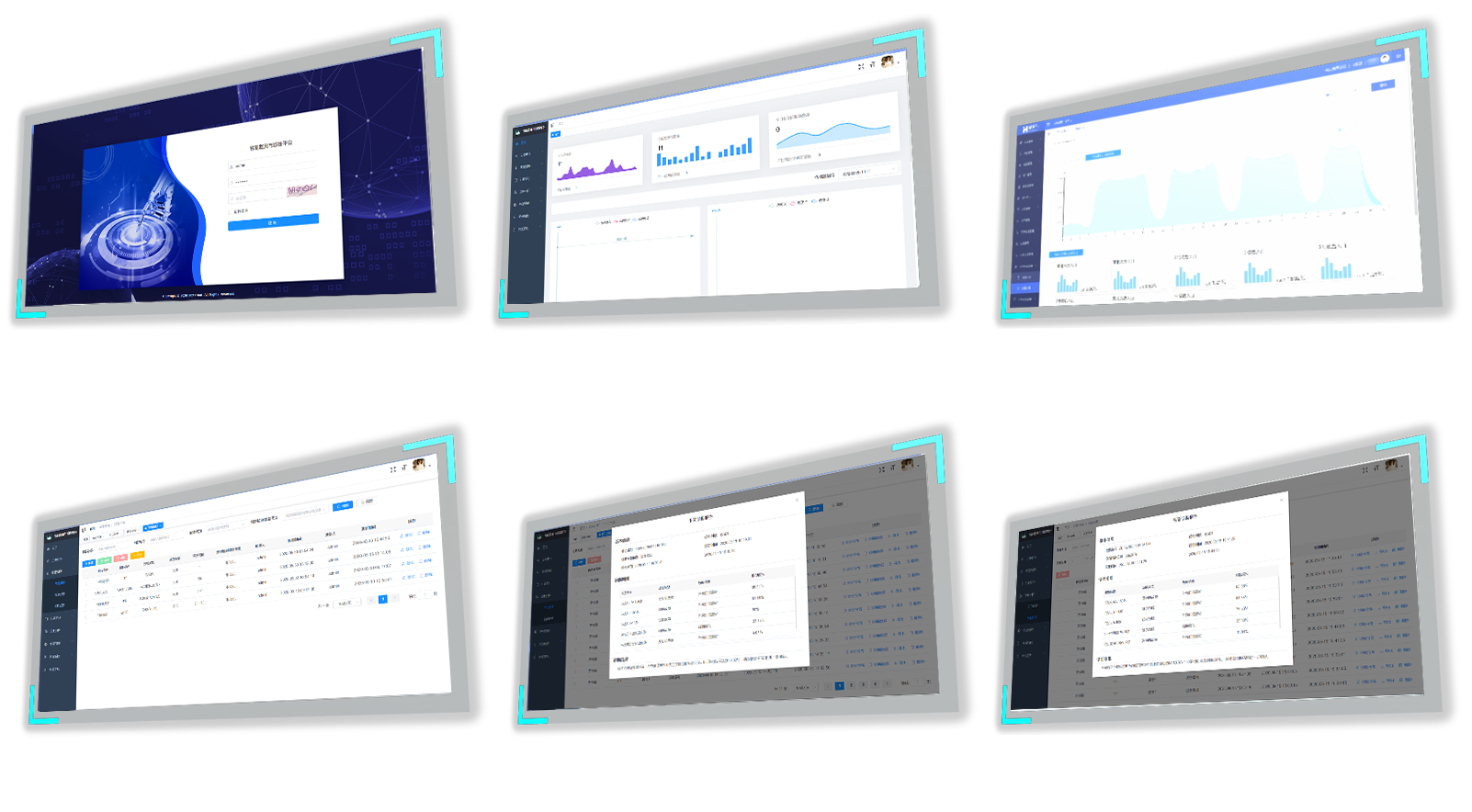

Monitoring:

Rely on wireless temperature and vibration sensor and other hardware equipment to collect terminal data, use big data to extract, compare, analyze and process. Through storage, loading, calculation and rendering, the real-time monitoring of equipment's acceleration, speed and displacement can be realized, so as to provide data support for intelligent early warning.

Intelligent early warning:

Through setting management, the user-defined early warning indicators can be realized. After collecting the equipment operation status and fault data, the neural network algorithm is compared with the fault model library to give real-time early warning for the abnormal situation in the equipment operation, and assist the staff to find the equipment fault in time.

Equipment management:

The platform realizes on-line unified management of gateway equipment, sensor equipment and parameter setting, and can realize gateway start-up and stop, loss of contact fault alarm, equipment addition, change and other operations. It is convenient for equipment expansion and maintenance management.

Model training:

The platform uses neural network algorithm, through the extraction of equipment operating parameters and feature recognition, the establishment of multi-dimensional algorithm fault model library, to provide diagnostic basis for various abnormal conditions of equipment operation.

Intelligent diagnosis:

It has the function of artificial on-line diagnosis and platform intelligent diagnosis. Relying on neural network algorithm and fault model library, it can diagnose the operation of mechanical equipment and issue diagnosis report to assist maintenance personnel in "predictive maintenance".

History query:

The platform provides record query of equipment fault information, alarm information and operation status information. It is convenient for users to look up the records of fault time, fault type and warning time, warning information and equipment history information, so as to facilitate maintenance personnel to troubleshoot.